With the increase in size of modern wind turbines, the importance of the tower for the costs of the turbine grows as well. At the same time, modern turbine design concepts require a lot of performance from the wind turbine tower design. How can we meet these requirements and still further decrease tower costs? In our history, we have designed all conceivable tower concepts and are constantly required to find creative solutions and to break new ground. This is why our customers can benefit from our experience today.

What benefits do we offer you?

- design of all tower variants from pre-design to certification

- innovative design solutions for optimization and cost reduction

- selection of a fitting tower variant for the turbine and the site, e. g. tubular steel, lattice, concrete, hybrid towers and many more

- application of state-of-the-art design methods from steel and concrete construction as well as mechanical engineering

- we comprehend the entire turbine system, are also proficient in the load simulation and can offer fitting control strategies for each tower concept

- we gladly provide the design of the foundation and the interface to the tower as well

Tubular Steel Tower

Lightweight champions

A lot is required of the tubular steel tower: it has to withstand fatigue loads, it must not buckle under extreme loads and its dynamic behavior has to fit to the other components of the wind turbine. We have developed solutions for each of these challenges that enable us to find the optimum tower for any turbine or site.

What benefits do we offer you?

- design of tubular steel towers (also for hybrid towers)

- we ensure a smooth certification process, anywhere in the world

- application of state-of-the-art design methodology to make best use of the potentials of the structure

- smart design solutions for a high fatigue strength

- interdisciplinary approach to finding solutions for high towers using simulation, controller strategies or the application of vibration dampers

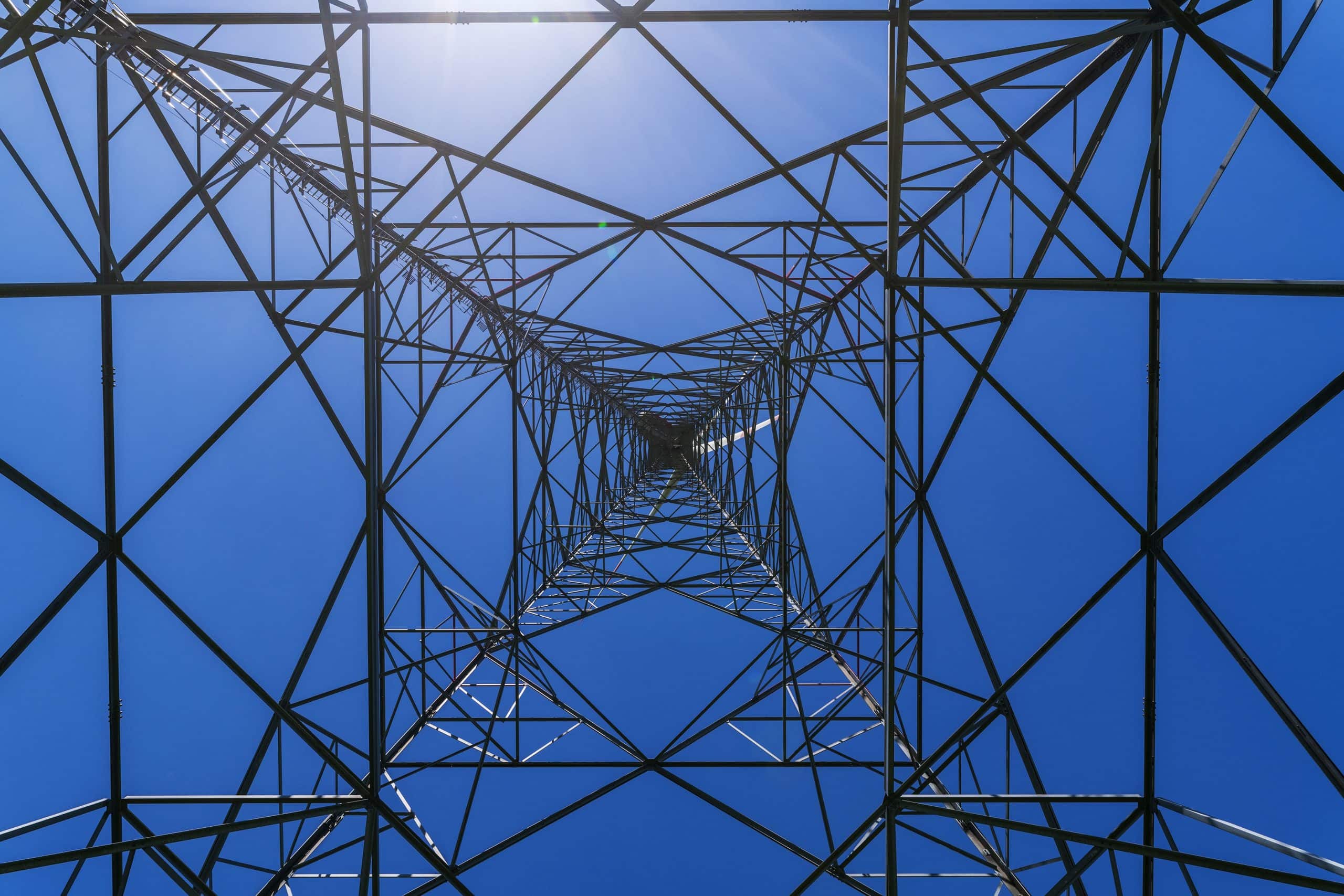

Lattice Tower

Better than its reputation

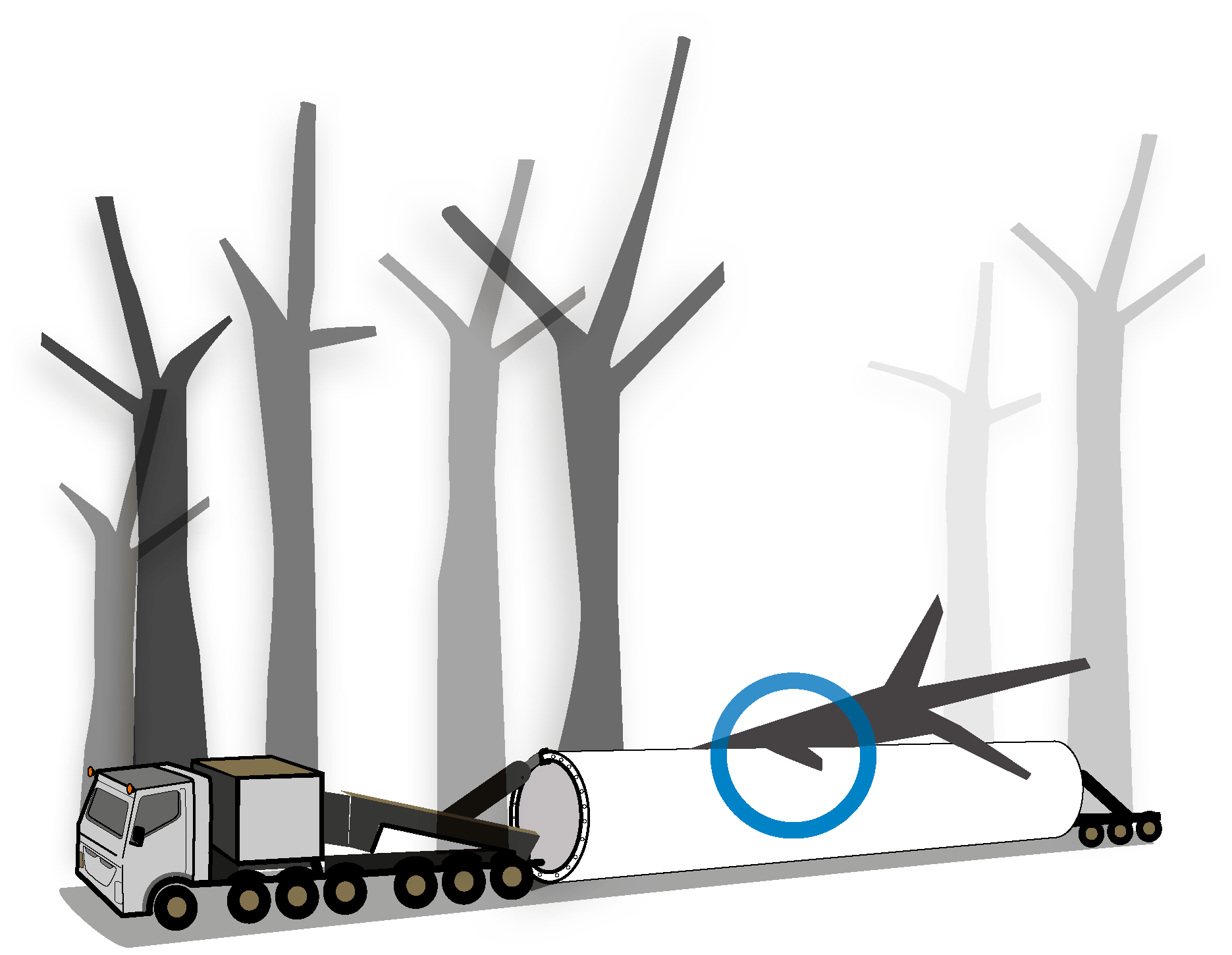

Lattice towers are not widespread but a good solution for wind turbines with large hub heights and special logistic boundary conditions. Compared to tubular steel towers, at large hub heights, significant savings in steel mass are possible. At the same time, the modular structure can be transported easily and the use of standard steel profiles allows for sourcing anywhere in the world. We guarantee that all connections are reliable and as low-maintenance as possible. Loosened bolts will not be found in our towers.

Lattice towers are not only of interest when carrying large rotors. Using lattice towers, we also bring radar and transmitter stations into great heights.

What benefits do we offer you?

- design and analysis of lattice towers for wind turbines or other applications

- innovative design solutions and design methods for economic tower designs

- consideration of the exact structure in the load simulation of the wind turbine

- solutions validated in the field that be securely bring through certification

- consulting for the maintenance concept

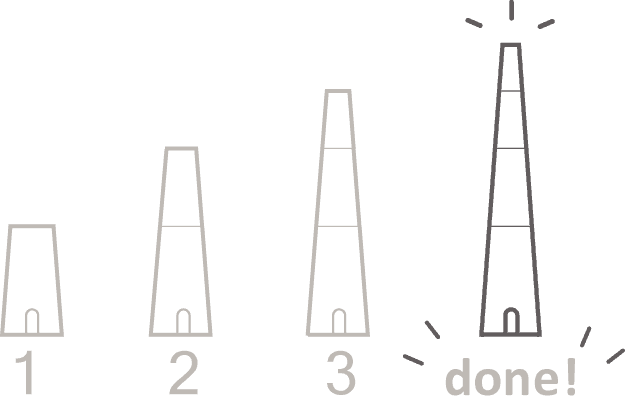

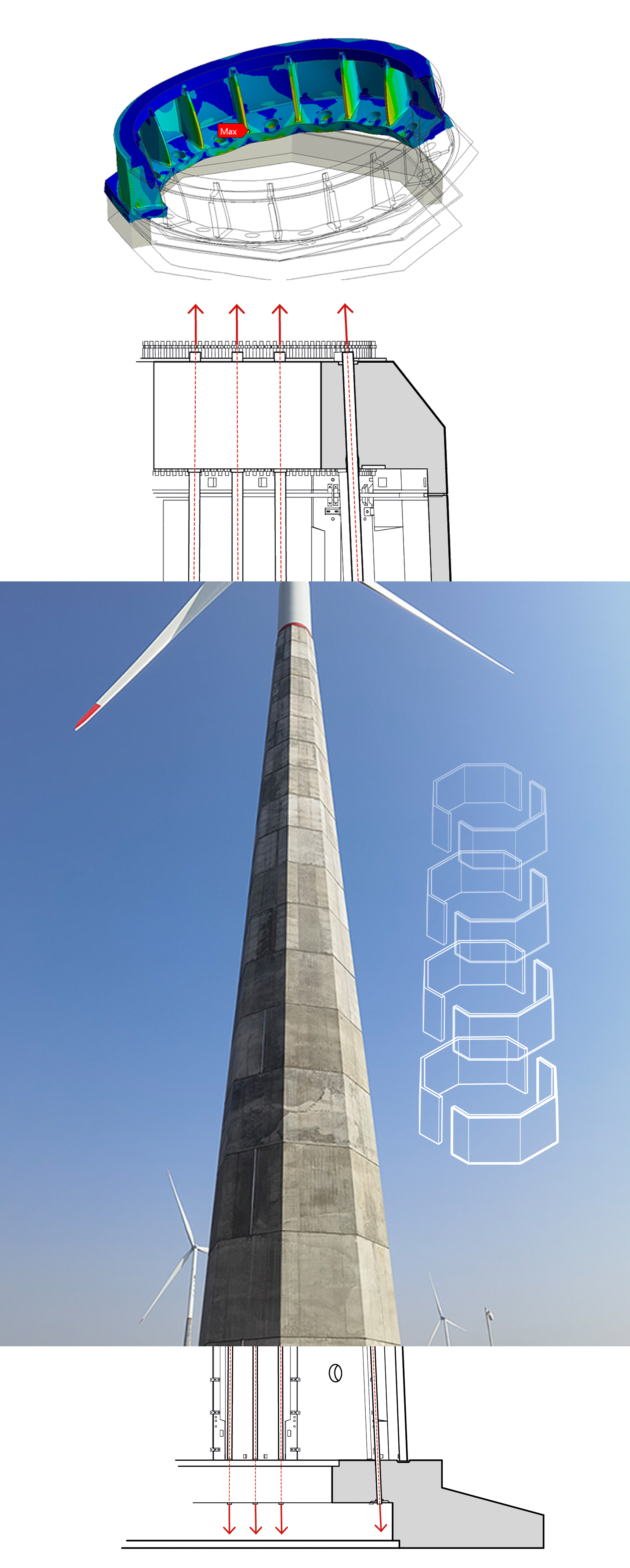

Concrete Tower

When swiftness is key

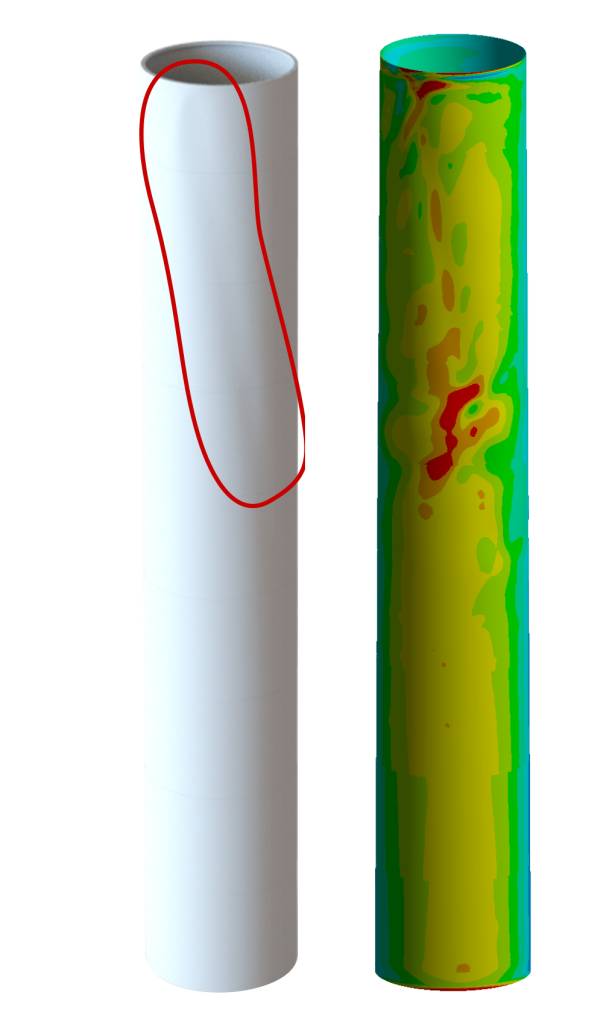

Concrete towers often offer logistical advantages over tubular steel towers. Large tower diameters can be realized because they are not limited by transport restrictions when the tower is erected piece by piece on site. The time required for assembly of the segments and the erection of the tower on site is a significant cost factor. We can minimize the construction period on site by employing smart concepts for the connection of the individual element. In addition, all the advantages we offer in the design of tubular steel towers take full effect for the upper steel sections of the concrete tower.

What benefits do we offer you?

- design and analysis of concrete and concrete hybrid towers

- innovative erection concepts to minimize the construction period

- the entire execution planning, including formwork and reinforcement plans as well as specifications for transport, handling and erection

- assembly monitoring

Concrete tower design by PEC

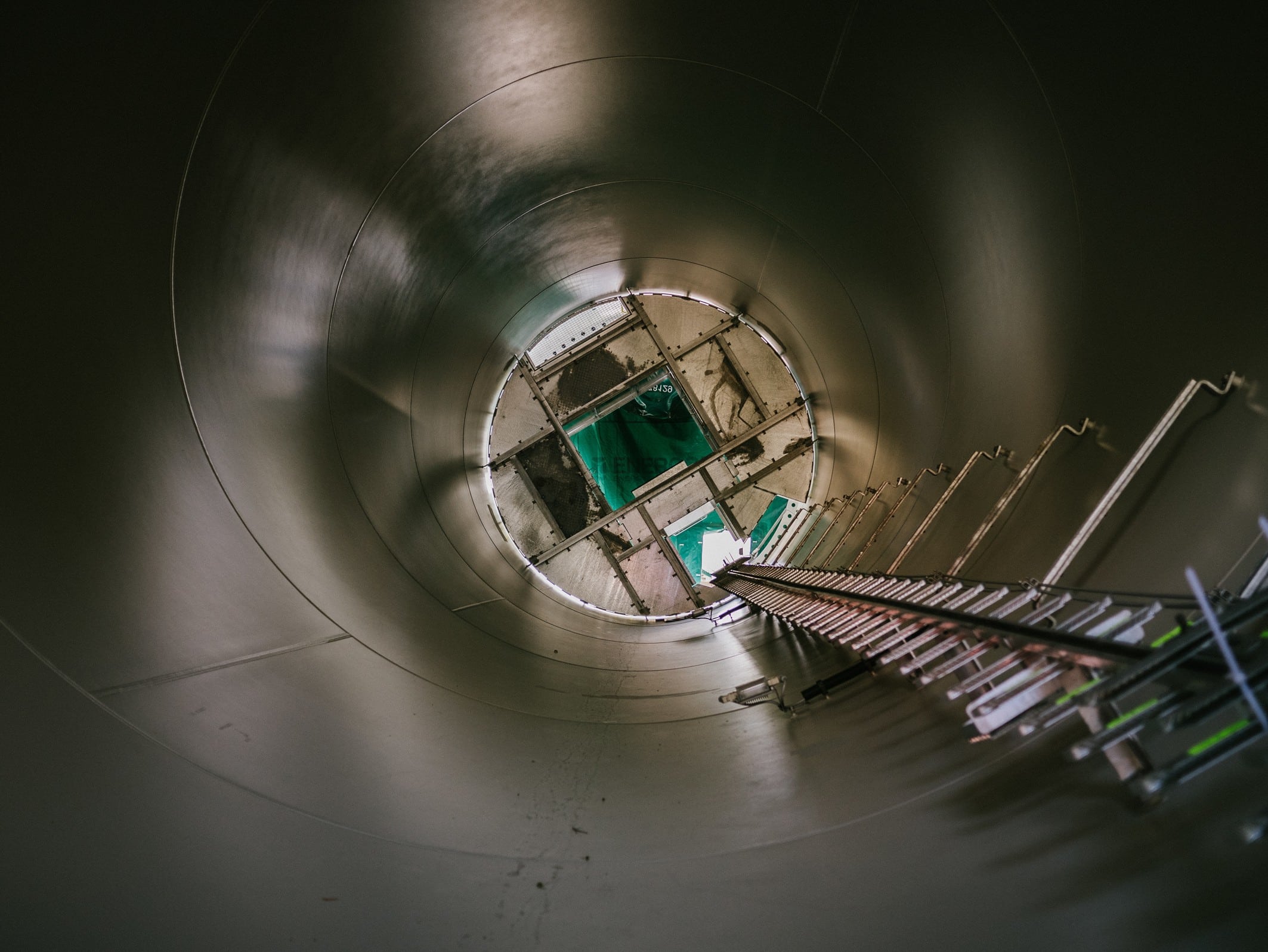

Internals

Talk about Secondary Steel!

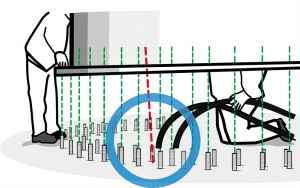

The tower internals are the secret stars in the tower design. The greatest successes in the structural design are ineffective as long as the interface of the internals remains the governing factor in the fatigue strength of the structure. Tower internals have to carry large static loads and also have to harmonize with the rest of the tower structure. This is why we not only offer design and analysis of tower internals but we find sound concepts for the overall tower design.

What benefits do we offer you?

- smart design solutions for the interface to the primary steel structure that guarantee a high fatigue strength (Design Category 90 or higher)

- design and structural analysis of all tower internals, e. g. platforms, internal and external ladders, crane beams or cable loops

- optimization of existing designs

- we securely bring the design through the certification

Tower – Dynamics

In harmony with the system

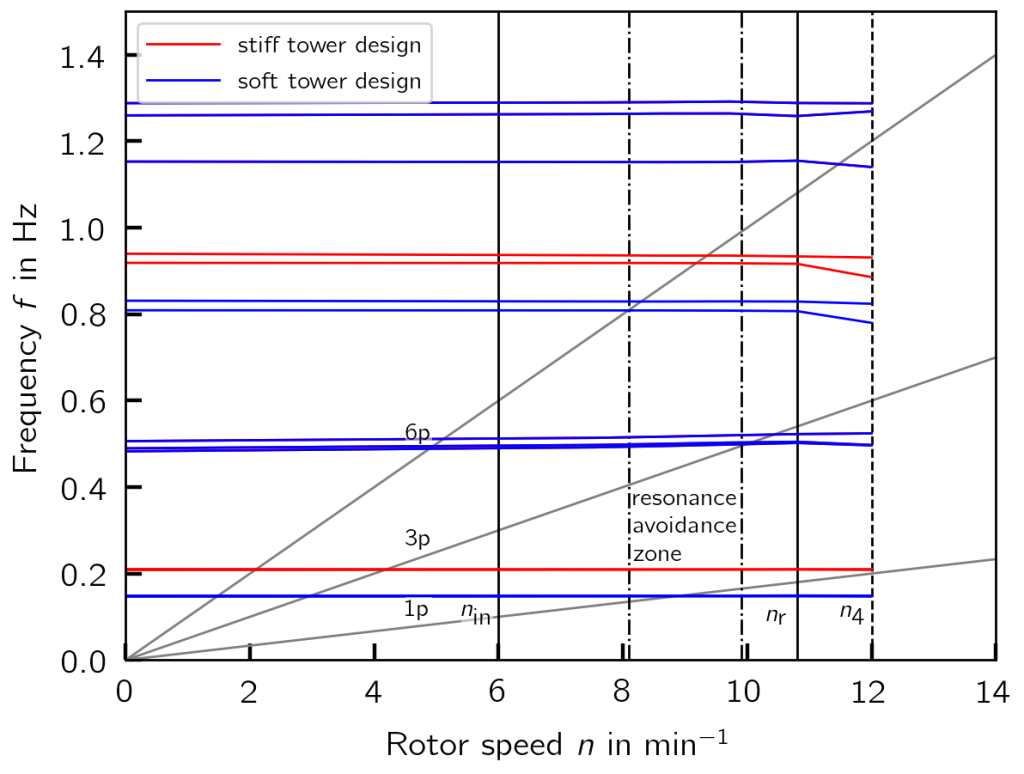

With the increase in rotor diameter and hub height, a stiff tower design where the eigenfrequency lies above the rotor speed is often no longer the most economically viable solution. Instead, a soft tower design where the eigenfrequency crosses the rotor speeds during operation allows to save a lot of steel mass.

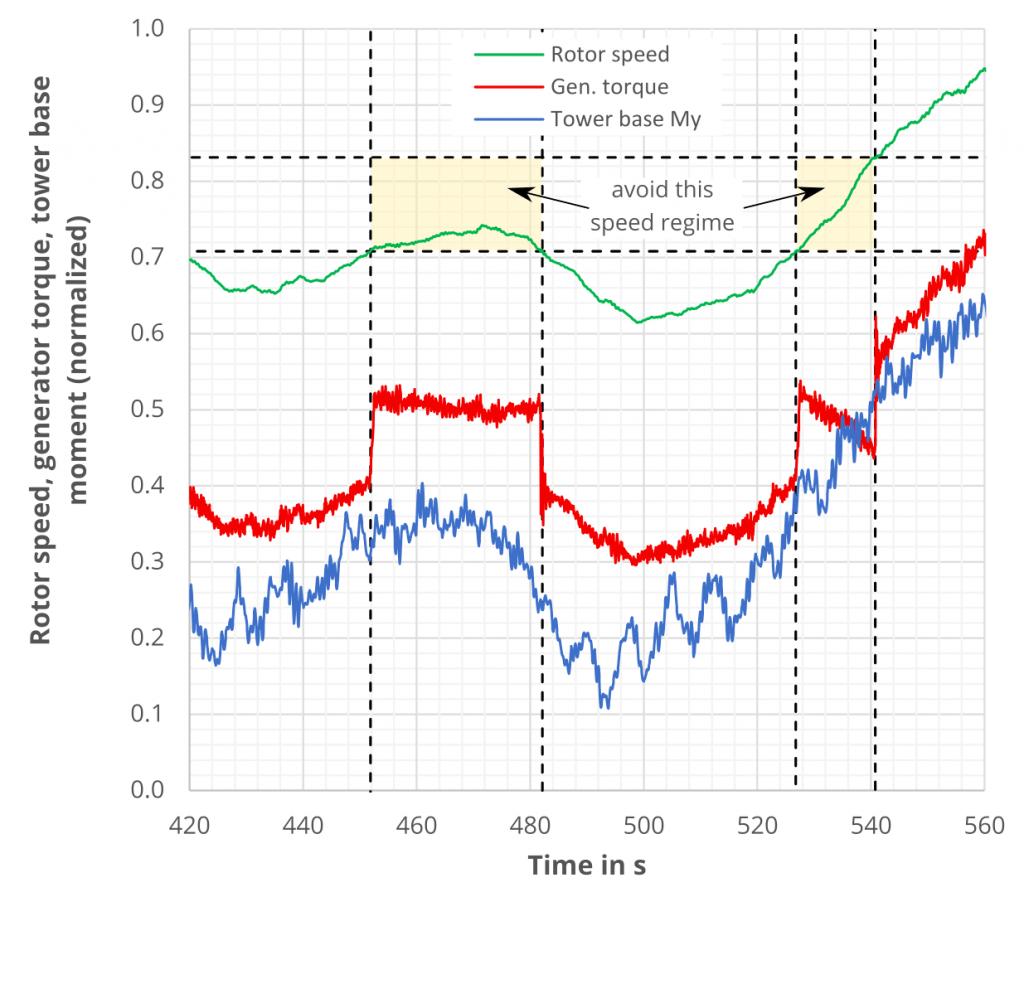

To make use of this benefit, the turbine controller must avoid resonant vibrations. With a fitting controller strategy, we can find an optimum eigenfrequency at which the fatigue stresses are minimized, maximizing material and cost savings.

What benefits do we offer you?

- parameter study to find the optimum structural dynamics of the tower regarding fatigue loads

- modification of the control strategy of the turbine to avoid resonances

- verification of the control strategies by load simulations

- adaptation of the controller strategy on the turbine hardware and tests in cooperation with renowned partners in the wind industry

- iterative optimization of the tower with load simulation and structural analysis

- design solutions to further reduce vibrations such as dampers

Campbell diagrams for the classical stiff (red) and soft (blue) tower designs with the rotor speed regime to avoid

Example for a generator controller that avoids the critical rotor speeds by allowing passing through the regime only for a short time

Tower – Fatigue

Showing stamina

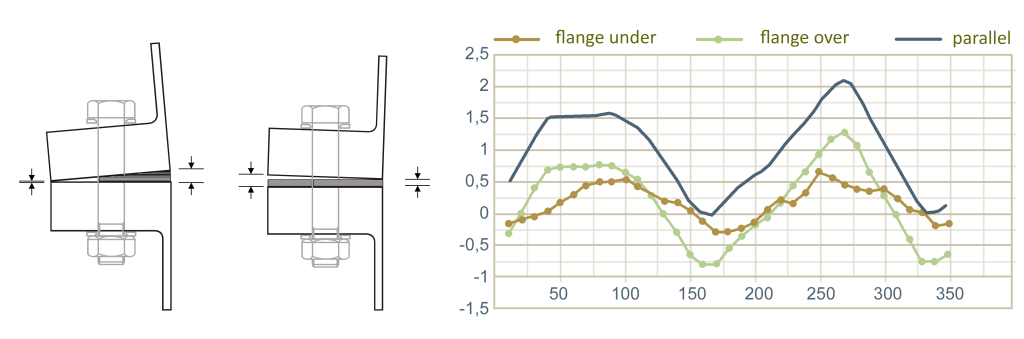

One of the largest factors affecting tower costs is the fatigue strength of the structure. Here, not only the primary steel structures such as tower shell, flanges and the door opening are important, but also the interfaces to the tower internals. Using smart design solutions, we can create benign Design Categories for the structures and connections that result in high fatigue strengths and allow for a cost-efficient design.

What benefits do we offer you?

- Design Category 90 or more without expensive custom solutions

- design solutions for all design details in the towers

- state-of-the-art design methods to find the optimum structure

- our solutions are accepted by all certification bodies

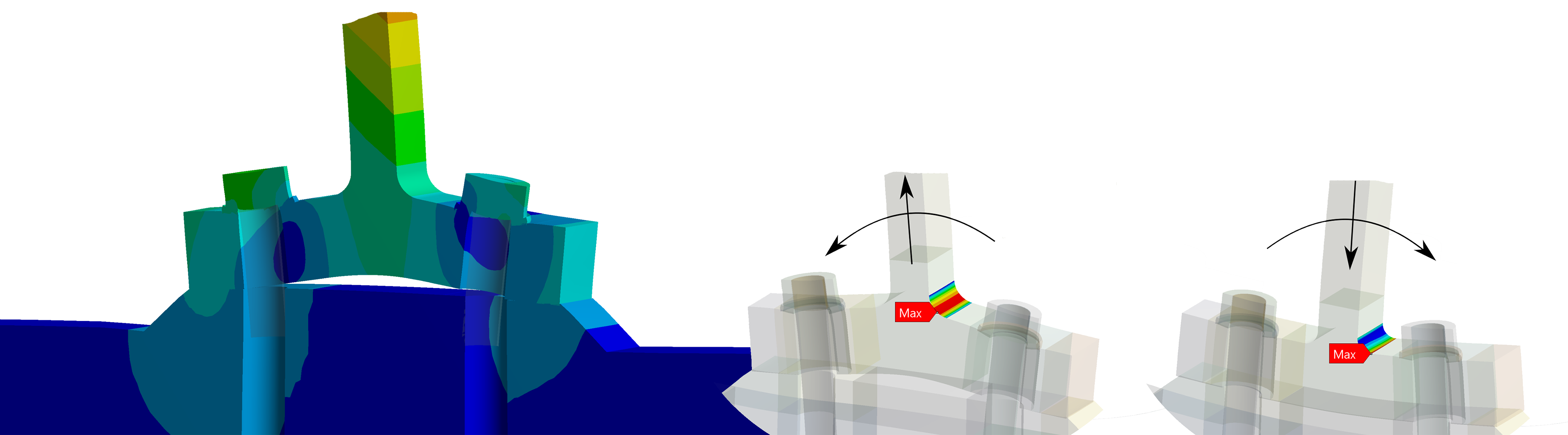

Numerical fatigue evaluation of the weld between the door frame and the tower shell

Numerical fatigue evaluation of the bottom flange radius to find a safe and economical design

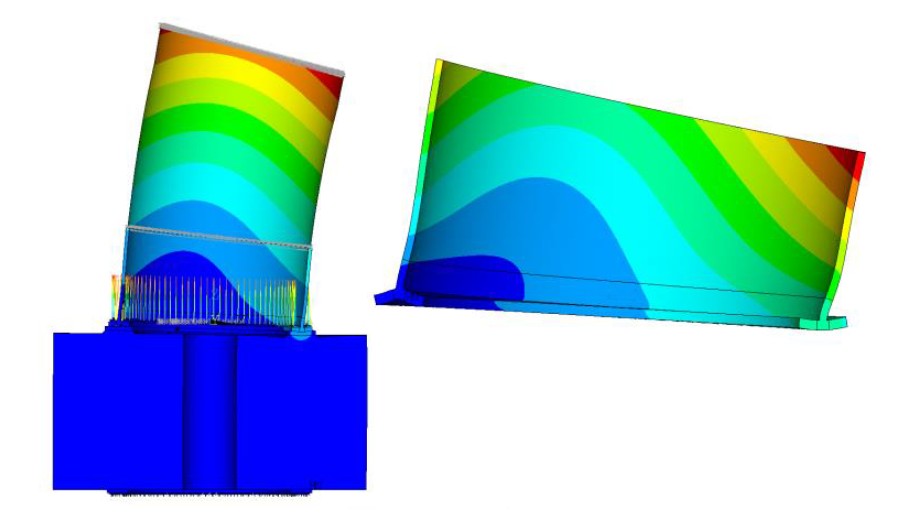

Tower – Stability

Utilize material strengths

In addition to fatigue strength, the tower has to be resistant to extreme loads – buckling must not occur. The recognized international standards leave us with many options to verify the stability. With little effort we can produce results that lead to a satisfying solution. In our experience however, it pays off to look into the details when performing buckling analyses. We apply the most modern analysis methods and further develop them with partners in industry and science. This allows us to consider the actual strength of the material and make full use of the bearing strength of the design.

What benefits do we offer you?

- state-of-the-art design methods to make optimal use of the design

- significantly more beneficial results than conventional methods can yield

- our solutions are accepted by all certification bodies

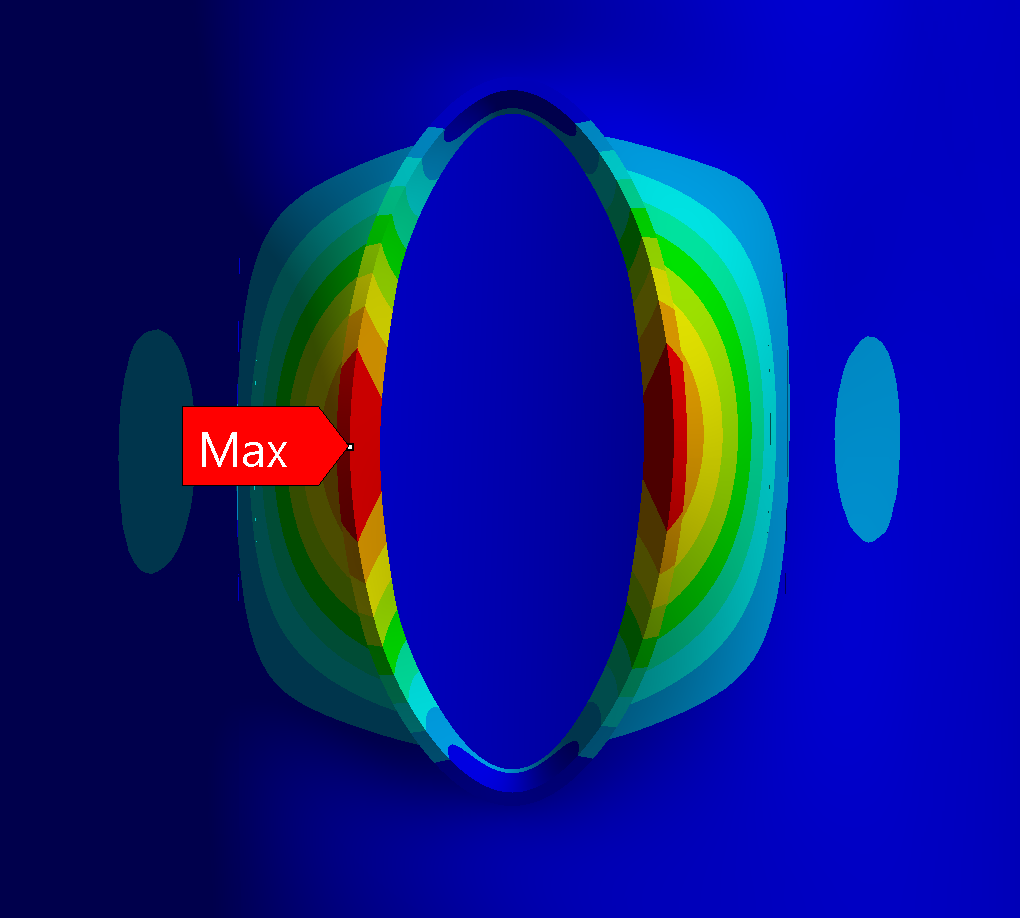

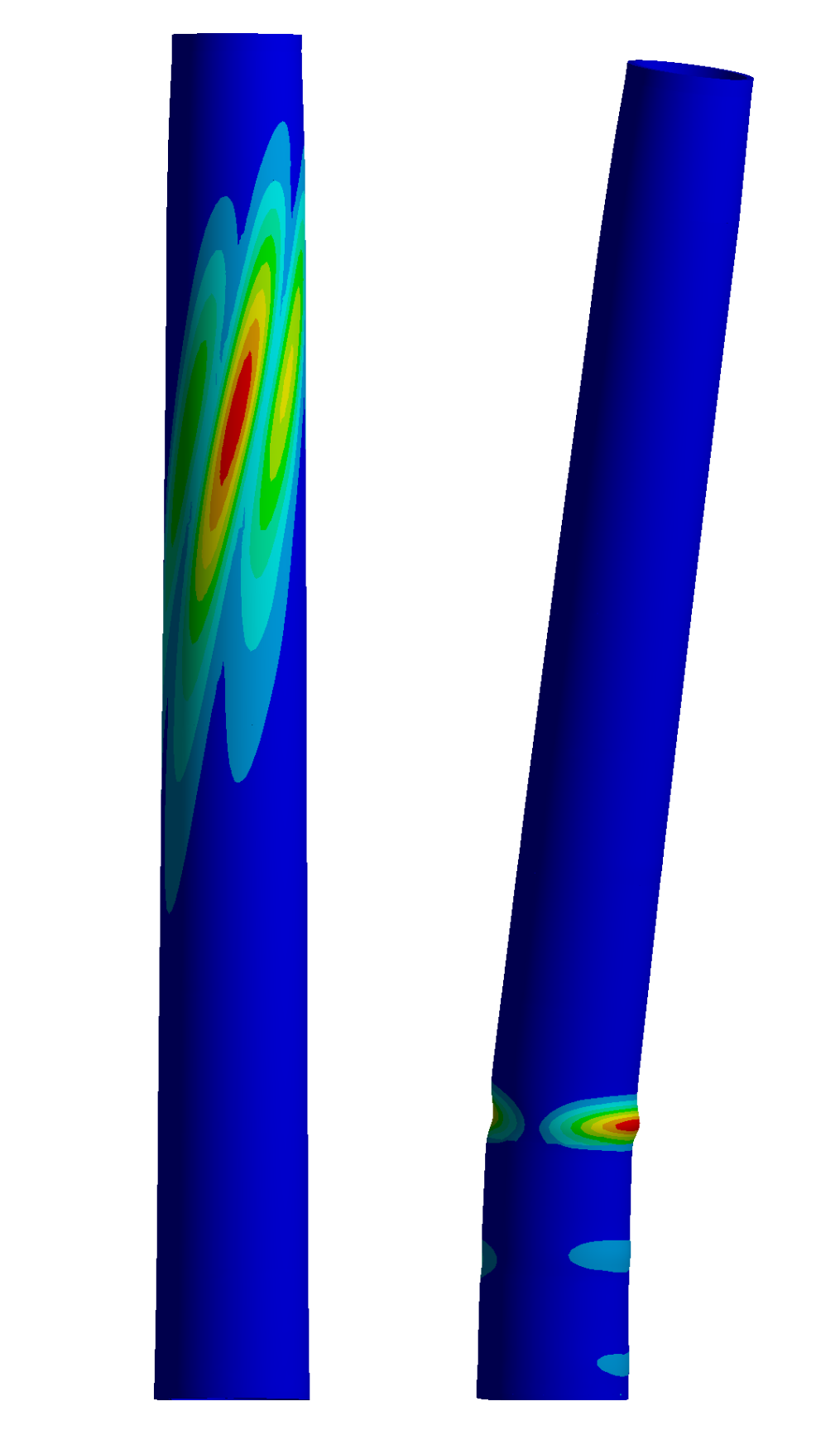

Numerical evaluation of stability in the area of the door opening

The stability can be proven even for pre-damaged structures: the required assessment can be done with a GMNIA

The combination of LBA (left) and MNA (right) enables an economical design of the tower regarding the stability failure mode

PE-90

Relief for the tower shell

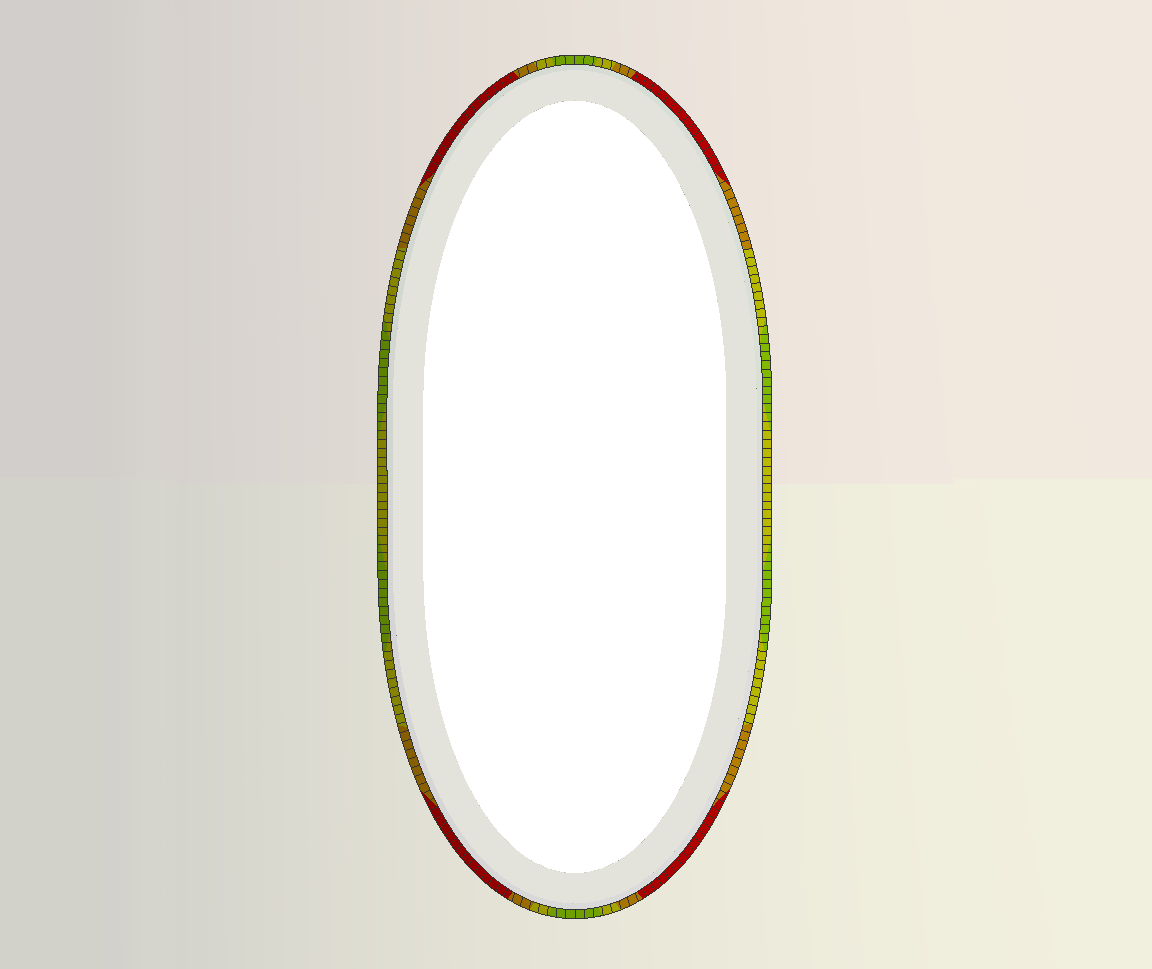

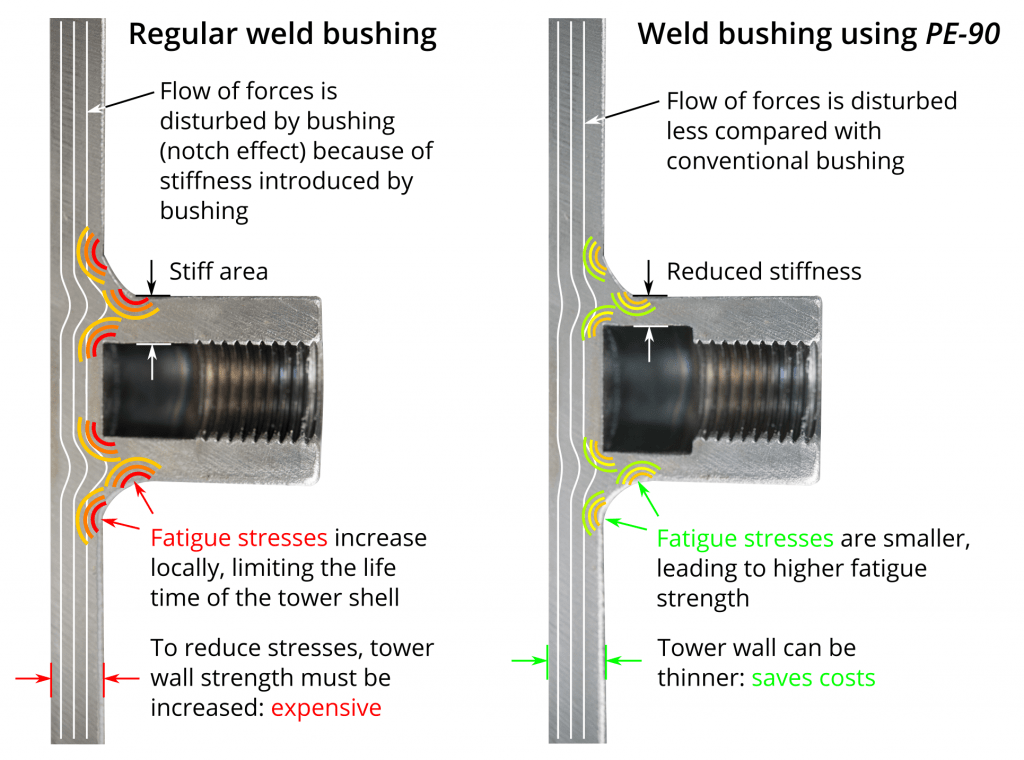

Weld bushings are an economical solution for attachment of tower internals to the tower shell. However, the weld bushings usually have a negative impact on the fatigue strength of the tower shell because of the poor design category, in turn making higher shell thicknesses necessary. Even worse: in reality, the design categories are even poorer than assumed in the recognized standards.

We have designed an innovative but simple solution to design weld bushings in a manner that they affect the tower shell as little as possible. Our patented solution PE-90 is named after its main advantage: we achieve Design Category 90 or better for the tower shell. This saves many tons of material in the tower compared with conventional weld bushings.

What benefits do we offer you?

- reduced cross section of the weld bushing at the interface to the tower shell

- locally reduced stiffness increases the fatigue strength of the tower shell

- Design Category 90 can be demonstrated for different geometries

- we find the optimal arrangement of weld bushings to sustain large static loads without impairing the design category

- the stress analysis to verify Design Category 90 is certifiable

Non-conformities

We got your back!

Despite high quality standards and great care in development, production and construction site, sometimes unforeseen events occur.

An unusual load situation leads to damage to tower and foundation or the foot flange does not fit on the anchor bolts of the foundation that have already been concreted in and has to be drilled out. In general, this is referred to as construction deviations.

On the construction site, where the error is detected, trouble might arise. Is a safe operation of the turbine guaranteed? How can the deviation be remedied as quickly and sustainably as possible?

We accompany our customers from the initial detection of the deviation to the evaluation and control of the implemented measures. It makes no difference what kind of tower or foundation has experienced. Our extensive experience in assessing structures and damages in the field helps us to pragmatically and decisively bring about a solution tailored to the deviation.

• we record the structural deviation quantitatively

• we propose suitable means of measurement, e.g. 3D surveying

• we assess the situation: how serious is the problem?

• we check the stability in accordance with building regulations

• if the stability is no longer given, we develop a solution

• we find a tailor-made solution depending on the type of structural deviation

• the solution quickly and as cost-efficiently as possible restores the safe operability of the facility